Client: Western General Hospital

The Challenge

Our client had installed two large sections of ductwork on the roof of the building and had subsequently retrofitted several branches of additional ventilation into the hospital ward below. During installation of various other services large sections of the original ductwork had become damaged, placing strain on the joints.

The ductwork that had been installed in the ward was squeezed into a very restricted space and once installed the ventilation was no longer fully accessible because of the way that other services had been built up around the ducting, which prevented the use of silicone which was normally applied around external joints and seams.

Consequently, leakage rates in the ductwork were higher than acceptable and it wasn’t possible to locate and seal the leaks without carrying out major work on the entire ventilation system. After 8-man weeks spent attempting to seal the ductwork in accordance with DW144 specifications, leakage rates remained unacceptably high. With the project drawing to a close and this problem continuing to cause delays, penalties were likely to be imposed for late project handover.

Our Solution

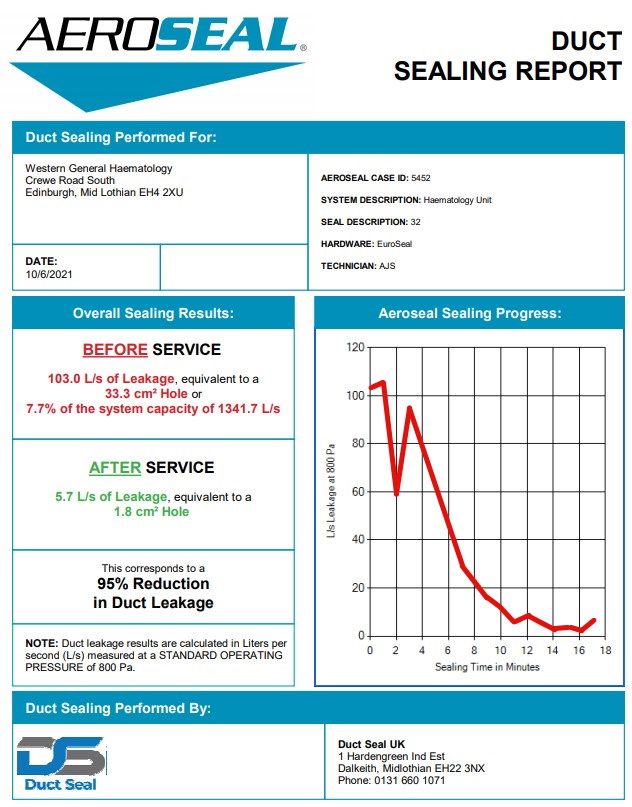

Our Aeroseal© product allows us to inject a PVA based glue into the ductwork in an aerosol form, sealing the duct work from the inside without the need to have any access. Over just three days we were able to repair 12 sections of ductwork. To ensure the solution is effective and all the leaks are sealed, the Aeroseal© system carries out a leakage rate test before switching over to the sealing process. On completion the same test is repeated to assess the effectiveness of the solution.

Aeroseal© works when it is injected into the ductwork under pressure using filtered dry air provided by a special compressor. The PVA aerosol is transported to the leak and attaches to the edges of any holes, before building up over a period of time until the hole is permanently sealed. The solution is permanent, flexible and waterproof and is ideal for use in clinical environments because it doesn’t coat the inside of the steelwork.

The Results

The location of the ducting and the different branches meant that the system was effectively broken into smaller sections. Within 2o minutes of starting the process around 95% of the leaks had been sealed, with the rest of the time being spent sealing up remaining smaller gaps in the system. . A further post seal leakage test was carried out and a certificate of sealing produced. On completion of the project the client also tested all the ductwork and reported that the ventilation system passed all the tests comfortably.